About Us

Infrared Asphalt Repair

There are three types of infrared repair equipment: infrared pavement heaters, infrared asphalt restoration systems and asphalt storing, recycling and hauling equipment. The cornerstone of the business is the asphalt restoration. This equipment is unique in the sense that it saves pavers, seal coaters, municipalities, townships and consumers a lot of money in repairs. Utility cuts and pothole repairs take roughly 30 minutes to complete with our Infrared machine. It is a seamless permanent repair. Infrared will outperform any conventional repair.

Conventional repairs and even newer chemical products such as liquid asphalt promise to be seamless, but are not. Many fill-tamp-and go repairs do not hold and will pop out once moisture penetrates in and around the seams. This is a waste of labor and material. With infrared, you are turning the existing asphalt back into workable condition, 2 inches deep. This process creates a permanent seamless repair resulting in high quality repairs on potholes, catch basins, drains, speed bumps, utility trenches. Any type of asphalt can be repaired, with minimal down time and normal traffic may resume immediately after repair.

Conventional Vs. Infrared Repair

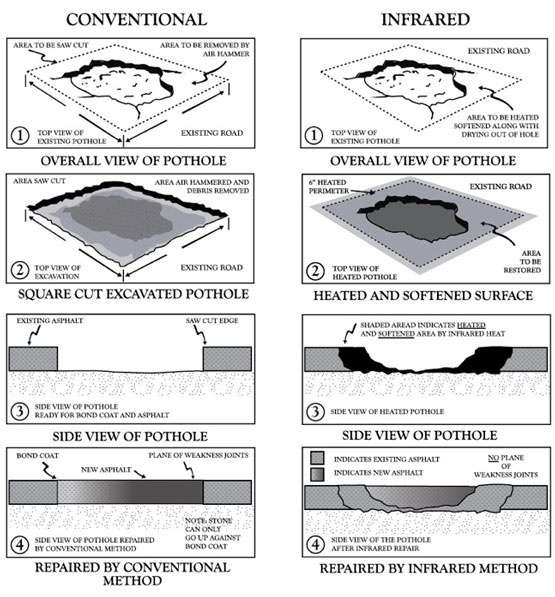

CONVENTIONAL METHOD

The area is examined and the old asphalt is cut and removed. The area is swept clean of loose material and water. The edges of the cut area are covered with bonding material and the new asphalt is added to the patch to the proper level, cleaned and then compacted.

INFRARED METHOD

The old material is heated and softened by means of INFRARED. As soon as the material is workable it will be raked 6 to 12 inches beyond the pot hole to blend the material together. New hot material will be added to the patch and then properly compacted to create a thermal bond to the surrounding pavement.